A few settings are needed for doing an EMAD calculation

When you want to set up an EMAD (= Earliest Material Availability Date) calculation, you need two settings:

-

Define the "Look ahead window" i.e. specify how far from now (= today) you would like to allocate component supply to component demand. This is done in the "VAPS Setup":

-

Define which kind of demand type should get supplied first, second, third, etc. This is done in the "EMAD Demand" dialog under "Manage -> Edit List". Here you can also change the priority order:

Consider the EMAD on production order routing line level

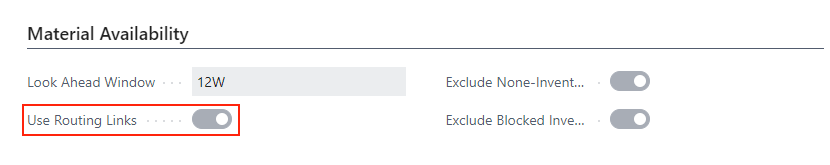

Without any further specification, the VAPS calculates the EMAD just on production order line level. Hence, there is no EMAD per operation at all. You can, however, have the VAPS also consider routing links so that the EMAD can be calculated by the production order routing line which means that a production order line can be started even when the material for one (or more) operations is not yet available. This option has to be switched on the VAPS Setup page:

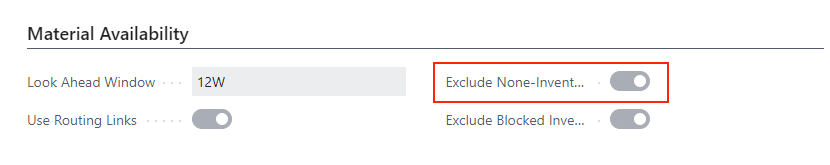

Exclude item type “Non-Inventory”

By clicking the according option, you can specify that the item type “Non-inventory” is to be excluded from the EMAD calculation.

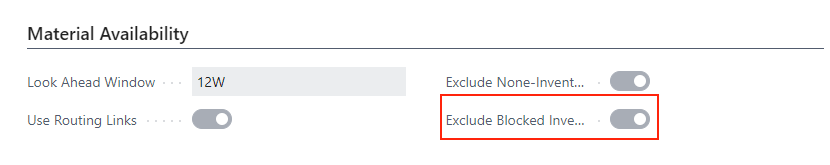

Exclude blocked inventory

You can easily and quickly block certain lots from the EMAD calculation. This could become necessary, e.g., if you have items the material of which is on-site, but need a further quality inspection. Then you could block them from the EMAD calculation, and we would treat them as not available.

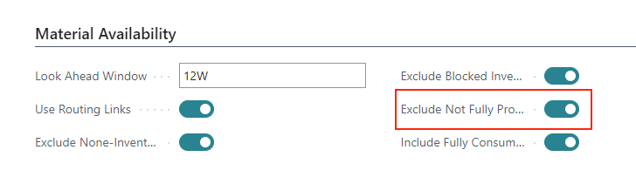

Exclude not fully promised receipt date from automatic functions like Add All

You can exclude production orders without a promised delivery date from the planning with "Add all" and "Add all incl. alternatives". You can still plan these orders manually per drag and drop.

Include fully consumed items into EMAD calculation

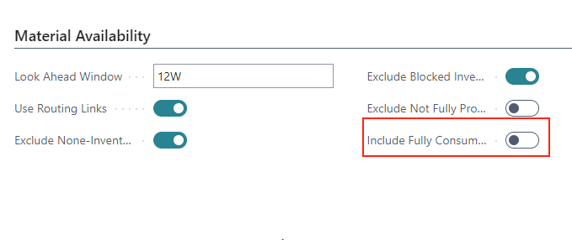

Planners can decide whether to include or exclude fully consumed items into/from the EMAD calculation by ticking the according option:

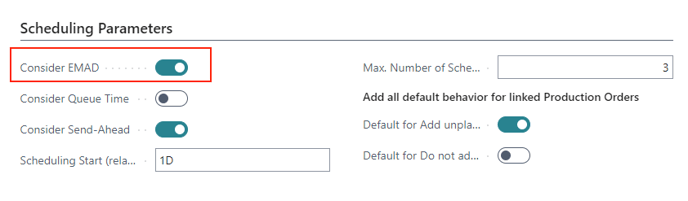

Consider EMAD in semi-automatic scheduling

The VAPS offers two semi-automatic scheduling tools, the functions "Add all" and "Fill idle times" either with or without taking into account the EMAD. The settings below make sure that these functions work properly. All settings can be found in the VAPS Setup:

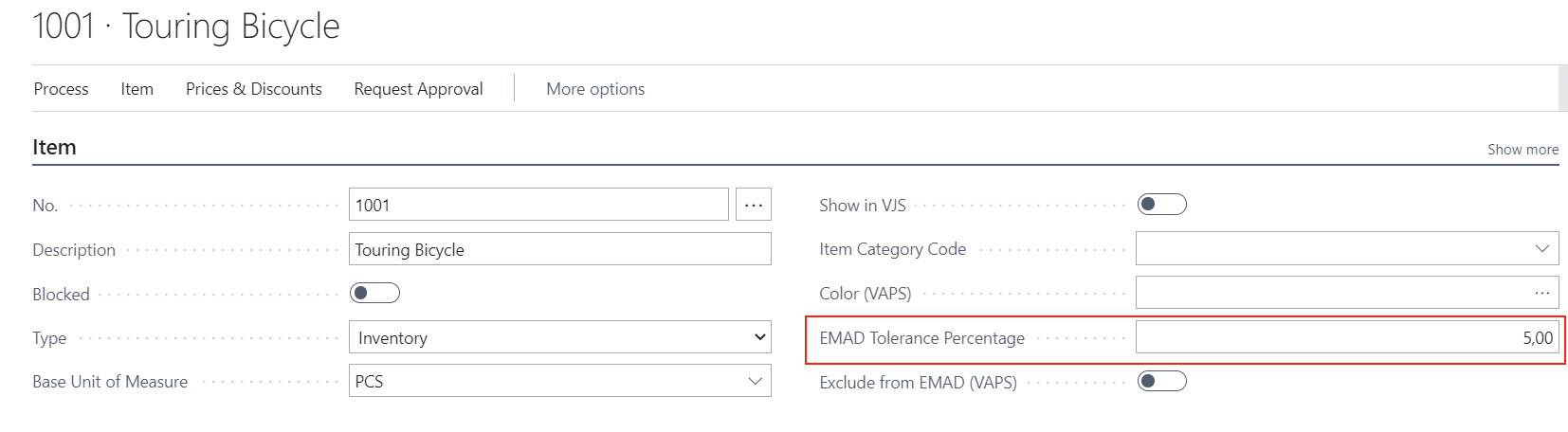

Apply EMAD tolerance to an item

As is commonly known, the EMAD calculation provides a date from which the required quantity of component demand is available and before which the production order must not start. The newly implemented EMAD tolerance allows defining the criterion not too narrowly so that, e.g., an order could already start if only 95% of the required material is available.

To be able to do so, we have enhanced the item card with the respective setting option. When calculating the demand, the entered value is multiplied by the available quantity.

Consider sub-locations when calculating EMAD

With this feature, we resolve the challenge faced by manufacturing companies that store materials in multiple locations. Treating different location codes as one tackles the issue of supply shortages at the production facility by offering a consolidated view of inventory across all relevant locations. Here’s why this approach works:

-

Unified inventory view: By treating all involved location codes as one, the system views the combined inventory levels, thus recognizing the overall available supply instead of seeing a possible shortage at one or two particular locations.

-

Elimination of short-notice transfers: The need for short-notice transfer orders is minimized since the inventory system accounts for the combined stock at all locations. This reduces the frequency of urgent transfers and the associated disruptions.

-

Accurate production scheduling: The VAPS will now schedule production orders based on the total available inventory, preventing the orders from showing up in red due to perceived shortages. This ensures a smoother production workflow.

-

Improved planning efficiency: With a comprehensive view of inventory, planning and replenishment processes become more efficient, leading to better stock management and reduced risk of supply gaps.

We have implemented this in the VAPS by enabling locations to have sub-locations, which is done on the Location Card:

Another dialog appears, where the user can define the needed additional locations:

When calculating EMAD, the sub-locations are consolidated with the main location, enabling inventory checks across all defined locations if the demand originates from the main one.

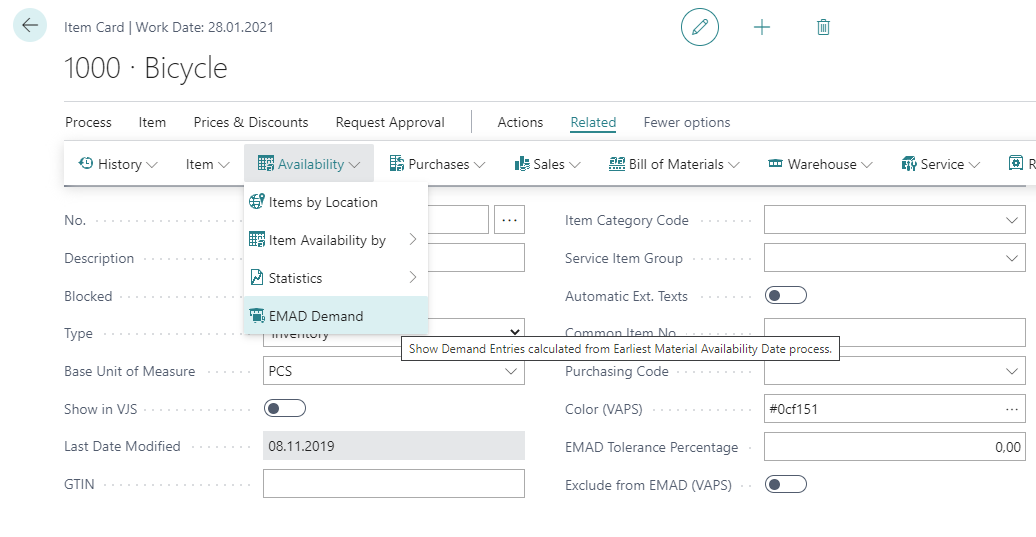

Shortcut to EMAD demand

On the Item card you can directly navigate to the EMAD demand entries.

Run EMAD calculation from Job Queue

With the help of the Business Central job queue, you can schedule certain background jobs for regular execution. The EMAD calculation, which until now could only be called via the VAPS (interactively with - depending on the data volume - long calculation times), can now be triggered via the job queue as soon as the VAPS is installed. Thus, it could be run at night, for example, without supervision and without needing someone to log on to the system to start the VAPS.

Setting up the job queue has to be done within Business Central by the administrator.