The VAPS lets planners see the impact on their schedule if unexpected incidents happen on the shopfloor.

Customers need and want to update their schedule based on actual data and if unexpected incidents happen on the shopfloor, they want to quickly see the impact on the schedule. This is exactly what the functionality offers. For easy and comfortable use, we implemented the following features:

-

Capability to load recent shop floor data (capacity ledger entries) into the simulation

-

Special color mode "Shop Floor Status View" to highlight deviations between actuals and schedule. The below screenshot shows the “Shop Floor Status View” with the default colors applied.

- Color mode “Execution Status View” to give feedback on the operations' status on the shop floor: "ready to get in progress", "in progress", "finished", and the "rest".

The screenshot below shows the "Execution Status" view with the default colors applied:

-

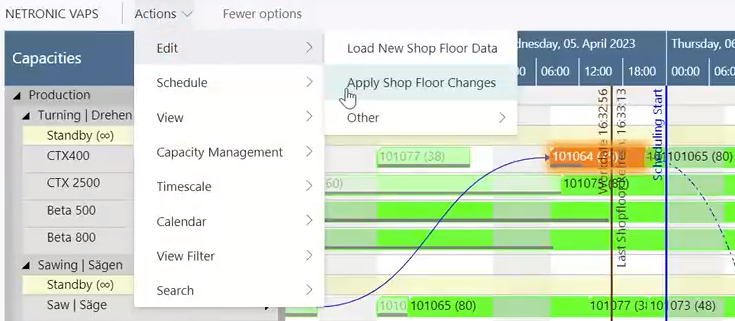

Option to (automatically) update the schedule based on actuals, either via the "Actions" menu or via the context menu

-

information from capacity ledger entries gets written into the production order routing lines

-

- Vertical line indicating when the last “update according to actuals” was made

Find more information on the Execution Status View in this article.

- Button in the status bar that turns yellow, when new warehouse acitvity line or shopfloor data is available. By clicking this button, users can also initiate these actions in addition to using the existing “Action” menu entries.