The VAPS supports setting up and visualizing subcontract work centers

Many manufacturers seem to use the subcontracting functionality of Dynamics 365 Business Central which implies setting up a work center as a subcontract work center. In general, two major use cases can be differentiated:

-

Subcontractor as standard operation

In some cases, manufacturers need to outsource certain steps of their production process, because they don't have the needed machines. In this case, they set up a routing and have a subcontracting work center (which equals their supplier) as usual step of this routing. -

Subcontractor as option to deal with bottlenecks

In this case, manufacturing companies do everything on their own. But there might be cases in which they want to outsource something to a subcontractor because all their machines are busy. In that case, their standard routing is on their own machines, but they can change it manually so that then they send one operation to a subcontractor.

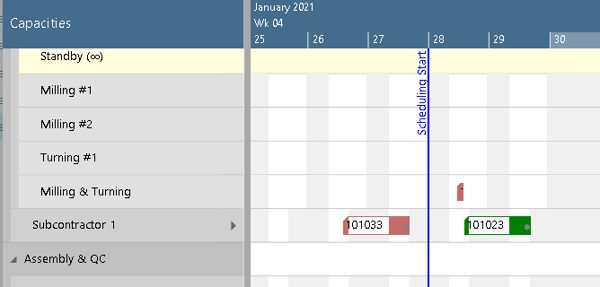

Since working with subcontractors is a really fundamental functionality for manufacturers, the VAPS enables visualizing and handling subcontractors as follows:

-

Subcontract work centers are treated as work centers with infinite capacities because capacities and availability of the subcontractors are unknown to us.

-

Subcontract work centers can be made part of alternate routing sets (although the rest of the VAPS currently still focuses machine centers when scheduling).

After having set up a subcontractor work center, operations can be assigned just the same as is done with "normal" work centers. However, please note that there is no Standby machine center.

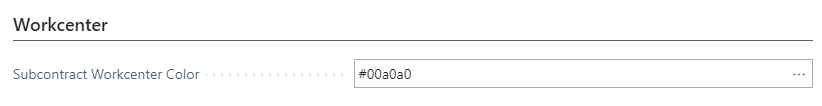

The default color of the subcontract work centers can be set in the "Color Setup":

Handling of subcontractor production orders with related purchase orders

If a purchase order mirrors a certain production order (and is used for communication with the subcontractor/vendor), the due date from the subcontractor production order is used for EMAD calculation. The reasons for this are as follows:

- in this constellation, the purchase order has no quantity (and hence cannot be used for EMAD calculation).

- There is also no reservation/tracking between the purchase order and the production order.