This feature is helpful for customers with a line-type scheduling approach

We've encountered certain customers who follow a line-type scheduling approach. Through collaborative sessions with these customers and their partners and a deep understanding of their processes, we've identified specific requirements that posed challenges with our initial VAPS design. This process revealed a plethora of potential features that could enhance the VAPS for more effective production line scheduling.

Recognizing the substantial amount of work involved, we opted to begin with a minimum viable set of features that would enable these customers to benefit from the VAPS immediately. Naturally, we plan to gradually expand this functionality with future releases.

As a first step in this direction, here's what we've implemented (and what we haven't):

Business Central setup

-

Define the line as work center

-

Define each “workstation” (i.e., each process step) as a machine center

-

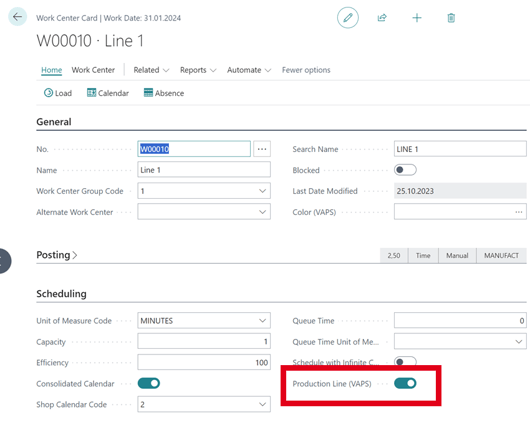

Flag the work center as “Production Line (VAPS)”

-

Example:

-

Work center = line 1

-

Machine centers of that work center

-

Step 1

-

Step 2

-

Step 3

-

Step 4

-

Step 5

-

...

-

-

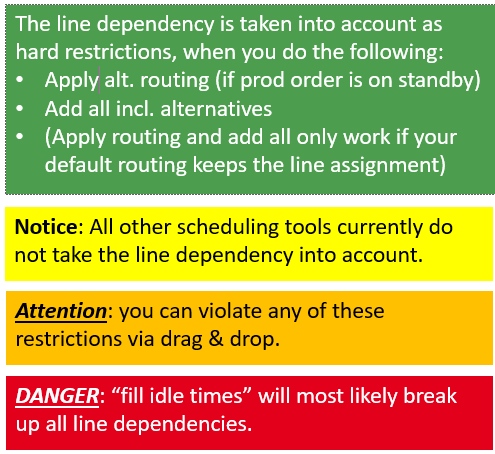

Scheduling: We take the “line dependency” into account

Example:

-

2 work centers flagged as “production line”

-

Both with 5 machine centers: step 1 … step 5

-

If the first operation of a production order is assigned to the machine center “step 1” within work center 2, all subsequent operations will also get assigned ONLY to machine centers within that same work center 2

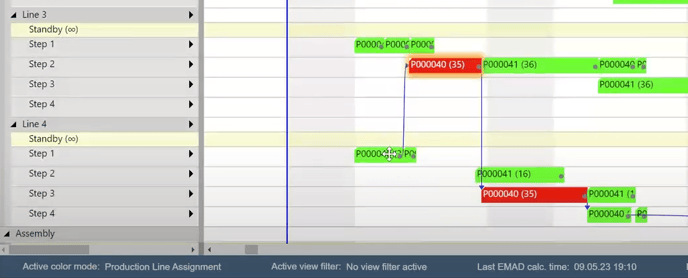

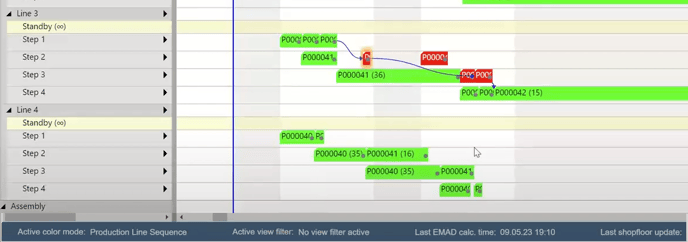

Visualization: We also monitor the “physical dependency”

-

Once production order 1 is on a certain line, it cannot be overtaken by production order 2

-

Hence, on each machine center in that work center, the operations of production order 1 must start and end earlier than the operations of production order 2

How to cope with the limitations

-

Two new color schemes

-

Production Line Assignment -> gives a visual warning if the “line dependency” restriction is violated (e.g., multiple operations from one production order flipping between lines)

-

Production Line Sequence -> gives a visual warning if the “physical dependency” restriction is violated (e.g., one production order overtaking the other)

-

-

Recommendations

-

Set your default routings in a way that the line assignment is granted

-

Set alternate routing sets so that you can efficiently “fill” all your lines

-

When doing line scheduling, trust the automatic scheduling

-

Avoid drag & drop as much as you can

-

If there are issues (sequence or line assignment violation), move the production order to standby and reschedule -> all line restrictions will be taken into account again

-