While working in a simulation, multiple changes can happen that are treated in different ways

To handle the possible changes that can arise while working in a simulation, we broke down these changes into different cases.

General changes to production orders

General changes to production orders while there are simulations (opened or not opened) that do not include these production orders are

- add new production orders

- delete production orders

- change "general" production order data, like

- due date

- required due date

- color

- quantity

- setup time for one routing line etc.

Effects of general changes

- the simulation gets outdated

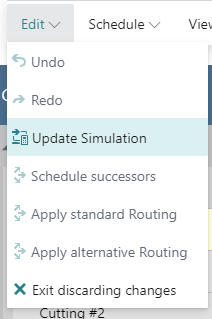

- you get a notification if this happens while a simulation is open

- you can directly update the simulation

A specific change to a production order: the status change

Changing the production order status can lead to a change of the production order ID, this making the handling of simulations rather tough.

Impacts of changing the production order status

- If you change the production order status from within the VAPS, we will seamlessly update the open (and all other simulations)

- If you change the production order status from antoher session/as another user

- all not opened simulations get silently updated

- in the open simulation: if you made a schedule change to the production order and somebody else changed the status while you did so, you will not be able to save your changes because the production order ID got changed.

A change to the production order routing line status

Changes to the production order routing line status can happen if

- somebody starts posting output/consumption on an operation from a released production order

- somebody finishes an operation from a released production order

Impacts of changing the production order routing line status

- the simulation silently updates