More comfortable long-term planning: automatic calculation of earliest start date

Usually, the fields “Earliest Start Date” on production order, production line, and production order routing line level have to be filled manually.

We have improved the handling on the production order level so that the “Earliest Start Date” on this level can be calculated and filled automatically. In particular, customers who often have orders whose required due date is relatively far in the future will appreciate this functionality.

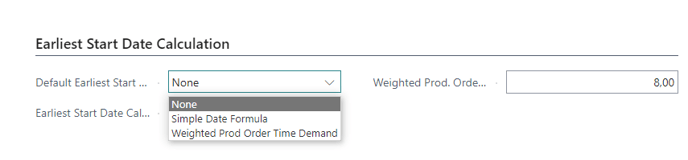

The settings for this can be found in th area “Earliest Start Date Calculation” Here you can define which mode of calculation should be used along with the associated custom values:

-

None – same behavior as previously

Recommended usage: If the shopfloor can manage the current production order volume, allowing for immediate ASAP planning without any need to “bench” tasks to align with the required due date so that storage cost will be minimized. -

Simple Date Formula - will be applied to the “Required Due Date” to fill the Earliest Start Date.

Recommended usage: If the shop floor must delay production orders to prevent long-term storage of components or finished items until delivery, AND if the average production order can be completed within a day or a few days of entering the shop floor with minimal variation between orders. -

Weighted Production Order Time Demand - encompasses all times (setup time, run time multiplied by quantity, wait time, and move time) to represent the total raw duration of the production order. This total is then multiplied by a user-defined factor and subtracted from the "Required Due Date" in real time (without using work/shift calendars).

Recommended usage: If the shop floor must delay production orders to prevent long-term storage of components or finished items until delivery, AND if the average production order spans several days, albeit with significant variation between orders. Recommended multiplication factor: on a one-shift Mo-Fr shopfloor, a factor of 8 would give the best results.

The settings of the VAPS dialog are taken as default. However, users also have the option to customize settings for individual production orders on the related production order card, which will overwrite the default settings from the dialog.

More details can be found here.