You might have work/machine centers that can do the same job. With the alternate routing sets, you can define these alternatives.

Plus: you can also define production (and setup!) coefficients if some machine/work centers can run faster than the others.

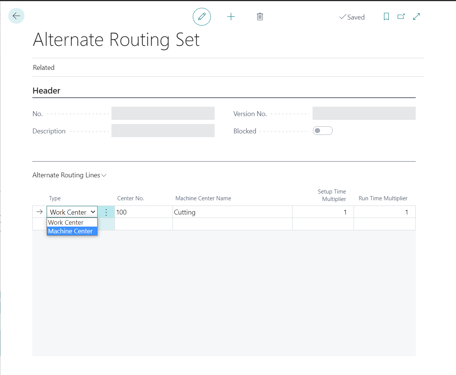

You can define alternative routings/ alternative work/machine centers on the "alternate routing set" page, which you can access from the NETRONIC VAPS menu, or by simply searching for "alternate routing set". The alternate routing set setup page looks as follows:

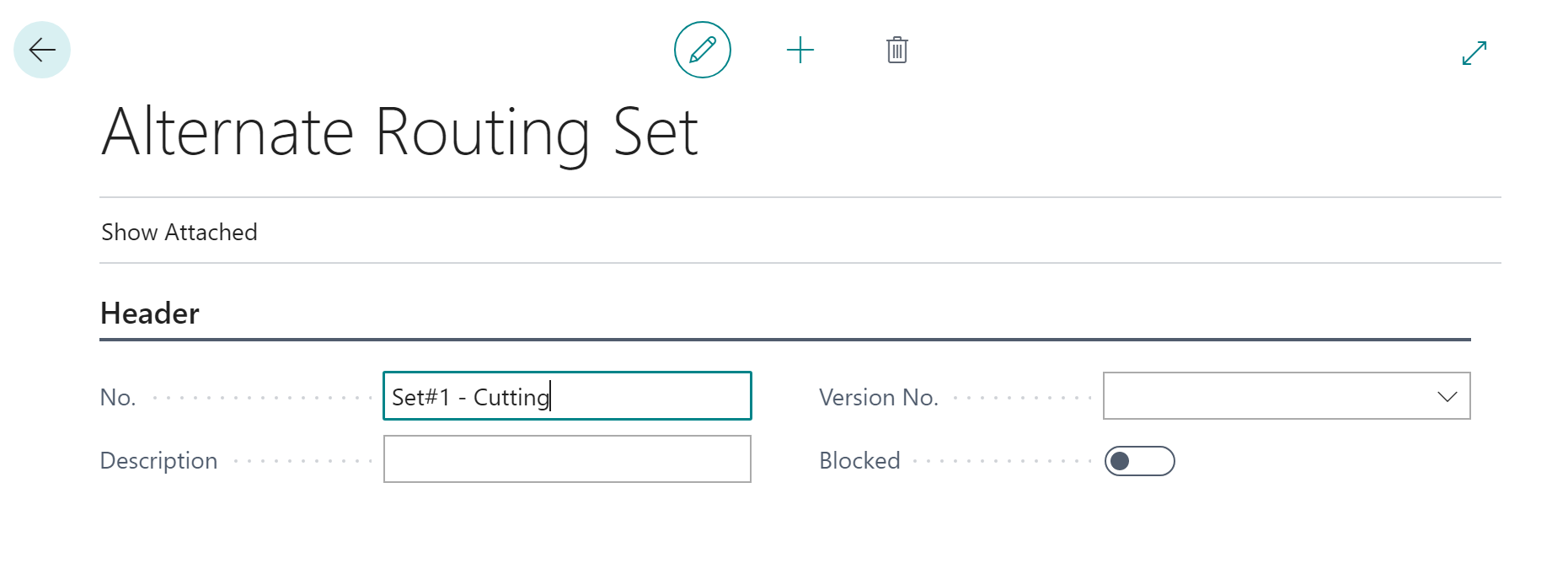

You then can create a new alternative routing set by clicking the "+" icon which you find at the top of the page. Then you need to give your routing set a unique number:

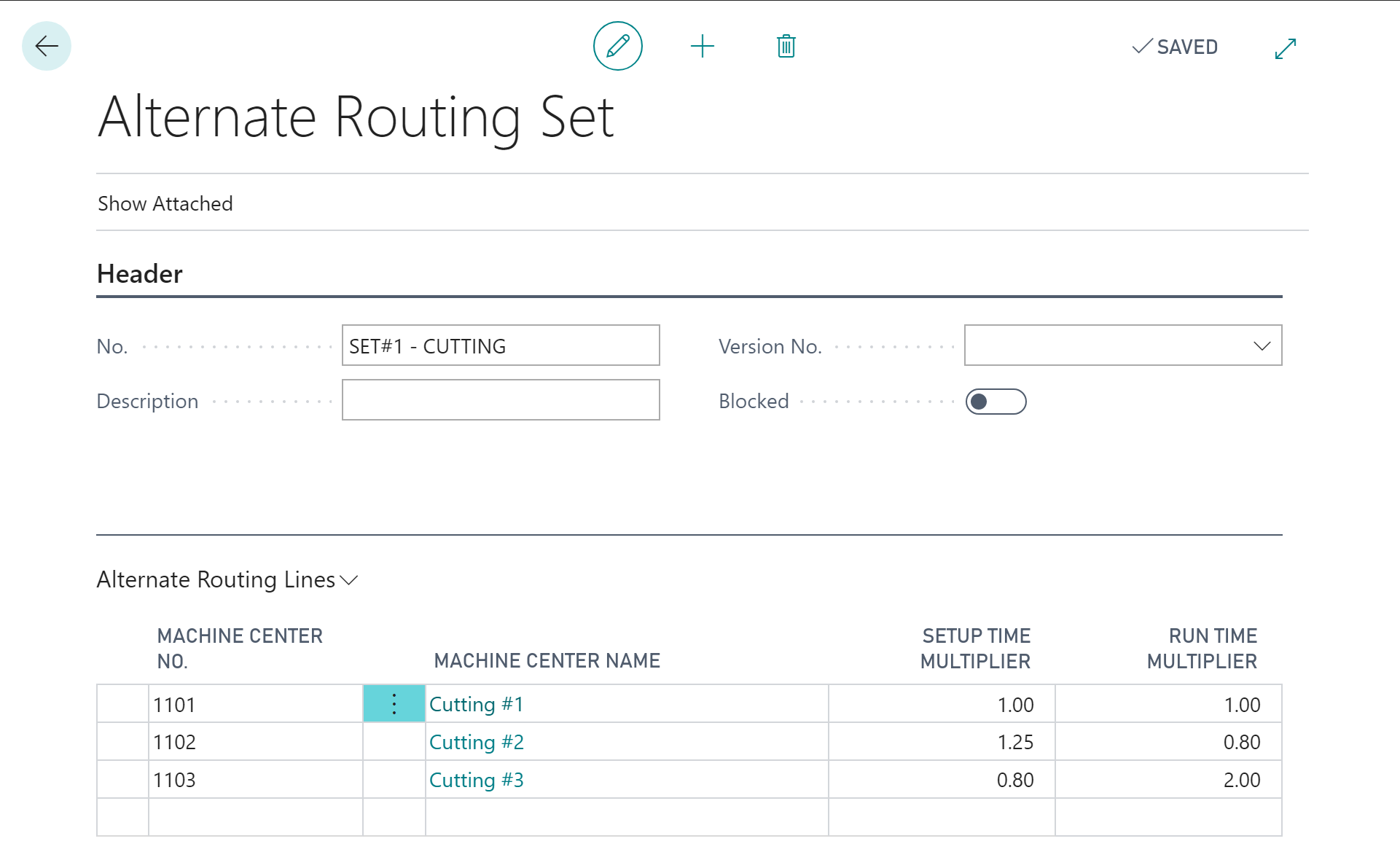

After that, you can add all those machine and/or work centers to the alternate routing set that can work as alternative resources within one routing.

However, you not just define the respective alternative resources. In addition to this you can also define two different types of production coefficients:

- The setup multiplier

- The runtime multiplier

In the above example, the alternate routing set "SET#1 - CUTTING" determines the following:

- The machine centers 1101, 1102 and 1103 (cutting #1, cutting #2, and cutting #3) are alternative machines.

- The machine center cutting #1 is the reference machine (both setup time multiplier and run time multiplier equal 1).

- Cutting #2 takes 25% longer to set-up than cutting #1 but can run 20% faster (only takes 80% of the run time).

- Cutting #3 can be set-up 20% faster than cutting #1 but runs 2x longer.

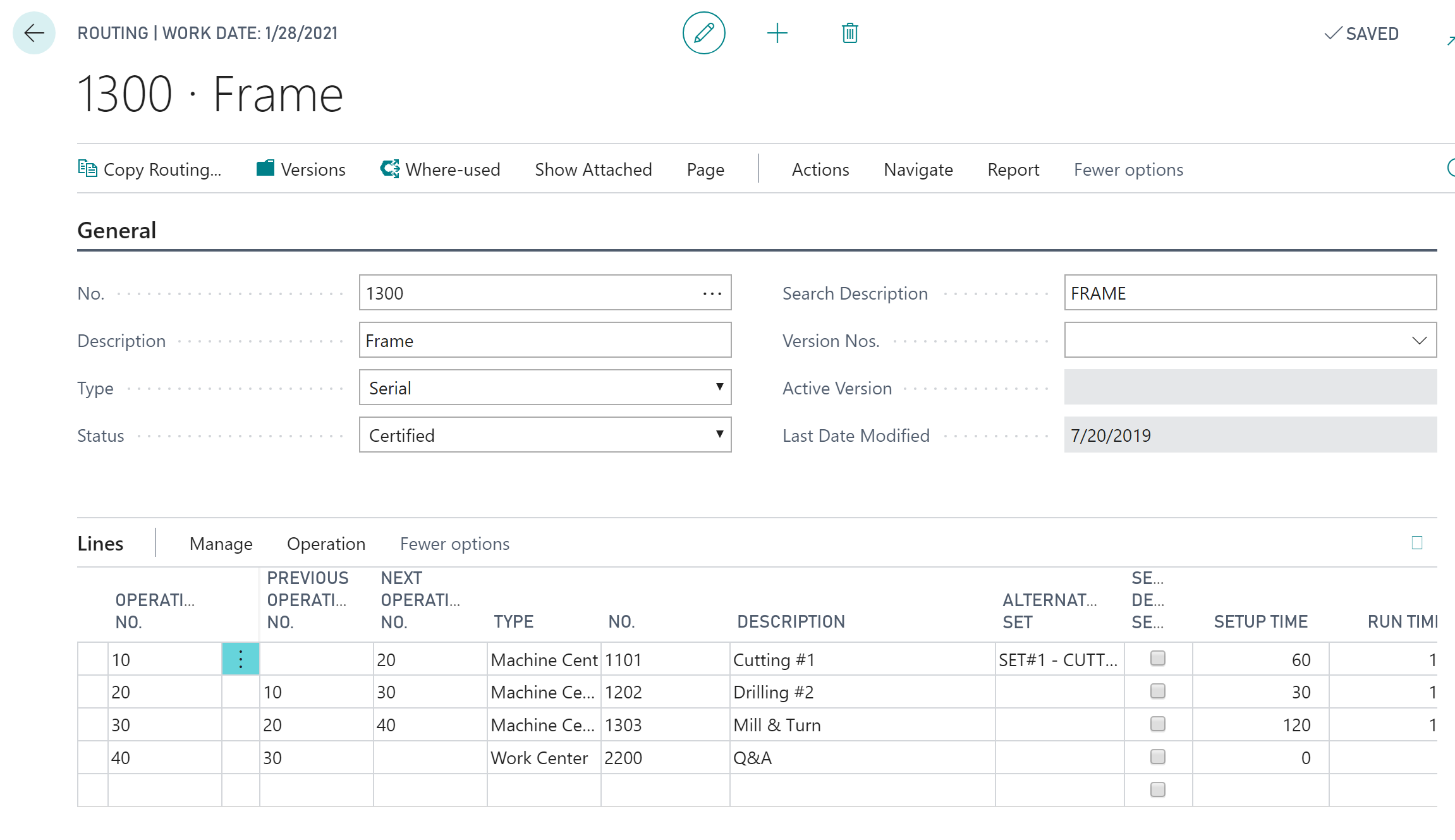

Once you have defined an alternate routing set, you can add it to any routing that you have.

The above example shows the routing 1300 for the item frame. Operation 10 by default is assigned to machine center 1101 (cutting #1). However, you see that the "SET#1 - CUTTING" is also defined as the alternate set.

When you now create a new production order using this routing, and when you then (re)calculate the production order via the standard Business Central scheduling, the alternate set is added to the production order routing line of that production order.

As a consequence, all alternative machine centers will get highlighted when you drag operation 10 of the routing in the planning board. Also, when you reassign it from cutting #1 to one of the alternative machine centers, the setup time multiplier and the runtime multiplier will get taken into account.