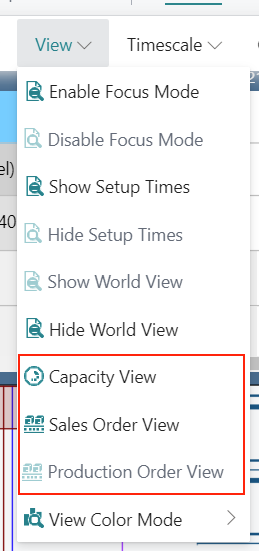

There are three different views in the VAPS: the Capacity View, the (read-only) Production Order View, and the (read-only) Sales Order View

You can switch between the views by the corresponding context menu items:

The Capacity View

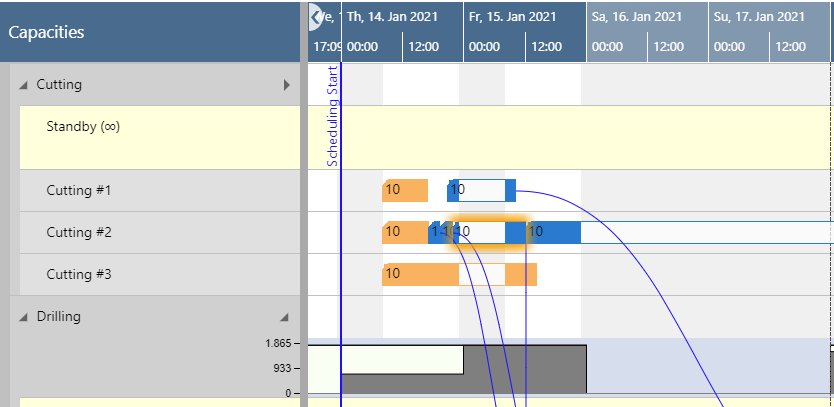

The capacity view shows capacity loads of work centers and machine centers, grouped by work center groups:

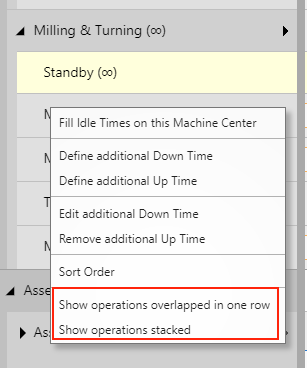

Select display mode for overlapping operations

Usually, overlapping operations are shown in an "optimized" way, meaning that the resource row with the respective operations gets extended in height so that the operations are completely visible. Since the VAPS schedules with finite capacity, overlapping operations are avoided, and hence this is a rare case.

However, some customers have contacted us with the following use case: They need to create operations with a length of zero to define a common starting point for parallel routings without blocking capacity. These operations will then be scheduled at the first possible position which will result in a very high stacked resource. For these cases, we added two new context menu items so that users can now decide whether overlapping operations are to be shown overlapped in one row or stacked. This also applies to resources on Standby.

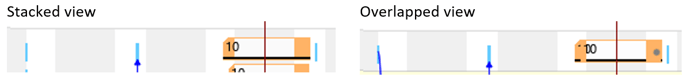

The picture below illustrates the different display modes:

Reorder the table per drag and drop

The table context menu offers an option to enable manual sorting per drag and drop:

Once enabled, you can, e.g., drag the “Wagner BAZ” machine center easily to another place:

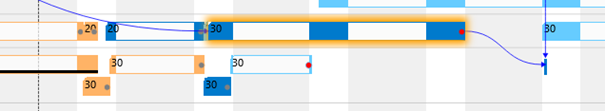

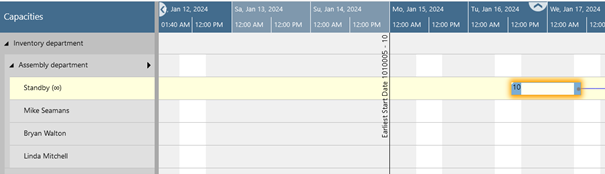

Visualization of the field "Earliest Start Date"

The VAPS comes with the convenient automatic scheduling functions "Add all", "Fill idle times", "Apply routing," and "Tighten operations". With the new version, users can limit these functions to only schedule production order routing lines/operations so that they start at or later than the date defined. This is done by the new field "Earliest Start Date" that has been implemented on production order, production order line, and production order routing line level. Clicking an operation with an earliest start date will display an according date line.

If the earliest start date is defined on all levels, the latest available date will be used for scheduling and if the "Consider EMAD" option is activated, this date will also be taken into account, meaning that the latest of all four dates will be considered.

Operations with an earliest start date can nevertheless still be dragged manually to an earlier start.

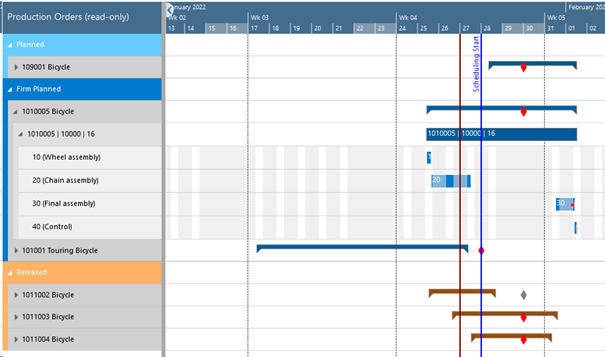

The Production Order View (read-only)

The Production Order View shows production orders categorized by their status.

The categories are indicated by different colors:

Production orders, their production order lines and production order routing lines are sorted in ascending numerical order. Within each production order, the relating production order lines with their production order routing lines are listed.

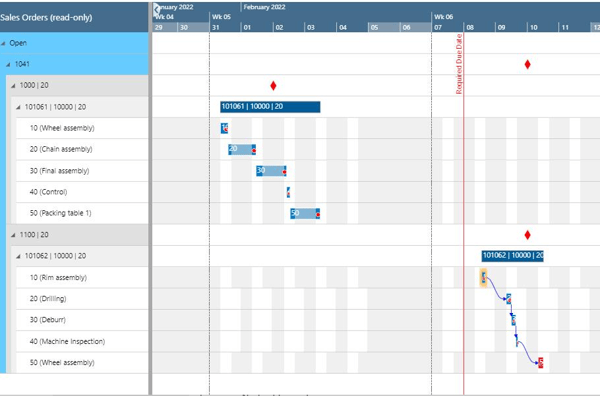

The Sales Order View (read only)

The Sales Order View shows those sales orders that have production orders against it and when those production order (lines) are scheduled. A visual alert is given if the production order's finish date is past the sales order's requested delivery date.

For better overview in large plans: the World View

Especially in large plans, it often happens that the planner loses herself a bit in the vastness of operations. To help them find their way and to not lose track of the overall situation, we implemented the "World View" that shows a small additional window underneath the actual plan and is available in all three views described above.

By dragging the red rectangle in the "World View", you can quickly shift your focus to another part of the plan.