At this point in time, the VAPS needs certain BC settings in order to run effectively and smoothly

The VAPS is built in such a way that it fully integrates with Dynamics 365 Business Central. It is our aspiration that both products – Business Central and VAPS – truly work hand in hand. However, the VAPS is a much younger product and as of now, it does not support every standard Business Central manufacturing functionality yet.

That means that at this point in time, the VAPS needs certain BC settings in order to run effectively and smoothly. This concerns a few BC fields that we have compiled in a list for you together with the recommended settings. You can differentiate between two cases:

- Fields that are not considered by the VAPS at all

- Fields that are considered by the VAPS

- For some of these fields, the VAPS automatically uses predefined values as shown in the list, and ignores other values.

- For some fields, we recommend you use the values given in the list. Otherwise, the VAPS might not deliver the expected results.

See here the list of fields that are affected (and by the way: we aim at making this list shorter the more we enhance the VAPS):

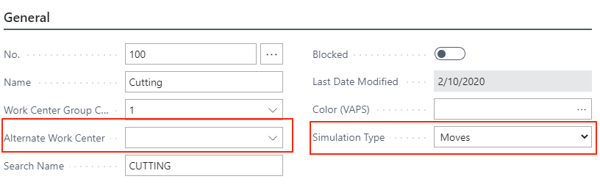

Work Centers

Fields not considered by the VAPS:

- Alternate Work Centers

- Simulation Type

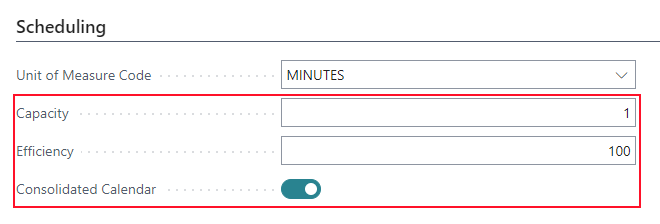

Fields that are considered by the VAPS

The VAPS might not deliver the expected results if you use another than the recommended value

- Capacity

- Efficiency

- Queue Time

- Consolidated Calendar = yes (Subcontractor = no)– in case you set this field to “no” the capacity curves might not be displayed meaningfully.

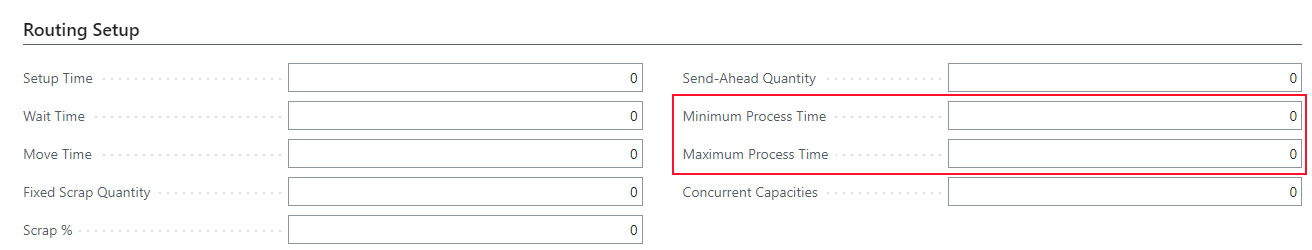

Machine Centers

Fields not considered by the VAPS

- Maximum/Minimum Process Time

Routings

Fields not considered by the VAPS

- Not considered for the routing if a sub-assembly / component is required for a later operation of the subsequent production order

- Maximum/Minimum Process Time