With the function "Add all" you can schedule a bunch of orders from Standby in one go, taking into account alternate machine centers, if desired.

Production orders that are not yet scheduled in the VAPS, are shown on the respective standby resource - a collection, so to speak, of orders that need to be added from the scheduler to the schedule. With the function "Add all" you can add them to the schedule all at once.

Of course, this doesn't happen at random but follows strict prioritization rules.

How it works

- Based on the assumption that late production orders are to be avoided, the VAPS automatically creates a prioritized list of the production orders that are on standby, proceeding as follows:

- calculating a buffer time per production order, following the formula:

buffer time = [required due date] - [end date of last operation as per BC] - starting with released production orders, then firm planned, then planned

- within each category, assigning the highest priority to production orders with the lowest buffer, the next highest to those with the next lower buffer, etc.

- calculating a buffer time per production order, following the formula:

- The orders are added to the schedule according to their priority

- The following settings can be made in the VAPS setup:

- define the "schedule start" date

- decide whether you want to take into account EMAD

- specify the number of iterations

More efficiency by planning per sales orders

Sales orders can have different priorities and planners often like to schedule them en bloc based on these priorities. This would ensure that the next free capacity is used in the best possible way for the corresponding sales order.

But, however, what if a sales order consists of, let's say, 40 items that on the other hand lead to 40 production orders? This is where it gets difficult because these 40 production orders are on Standby with the other production orders.

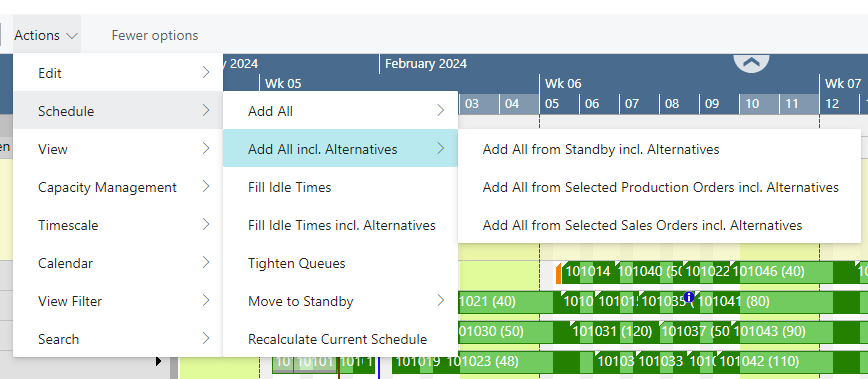

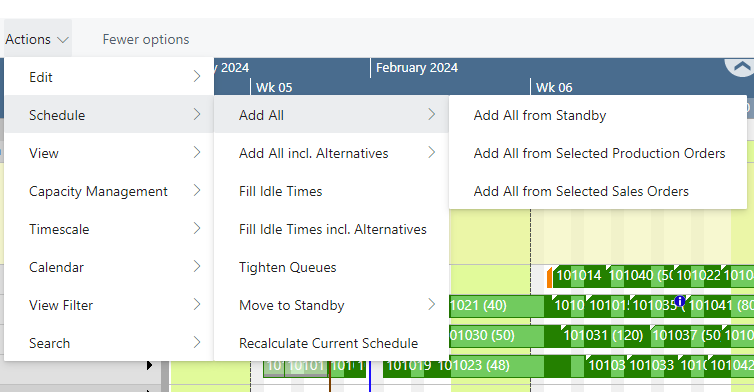

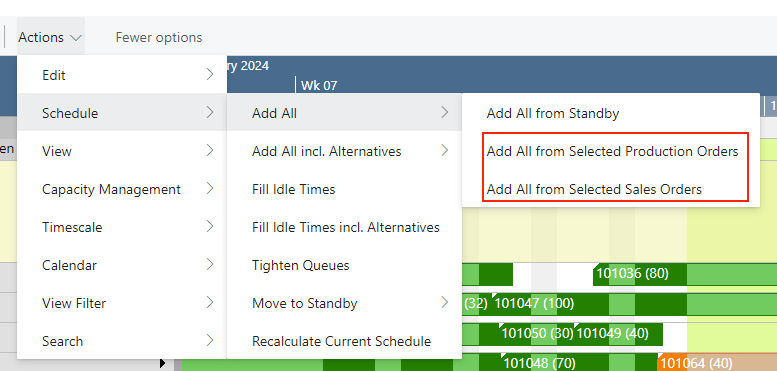

Two according options in the "Add all" and "Add all incl. alternatives" menus offer to solve this problem:

The options in detail:

-

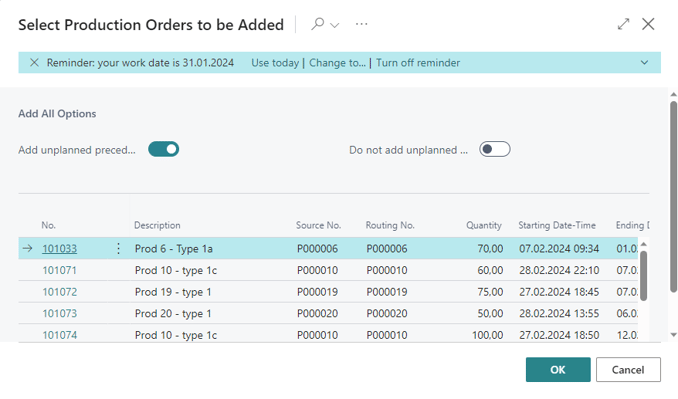

"Add all from selected production orders" shows a list where you can select from all production orders where at least one operation is still on standby:

-

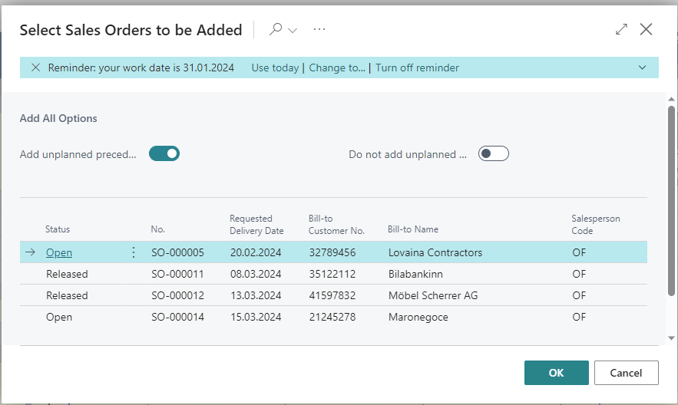

"Add all from selected sales orders" shows a list where you can select from all sales orders with an assigned production order where at least one operation is still on Standby:

In both dialogs, you can change the order by "Move up" and "Move down":

Regulate the behavior of preceding and succeeding linked production orders

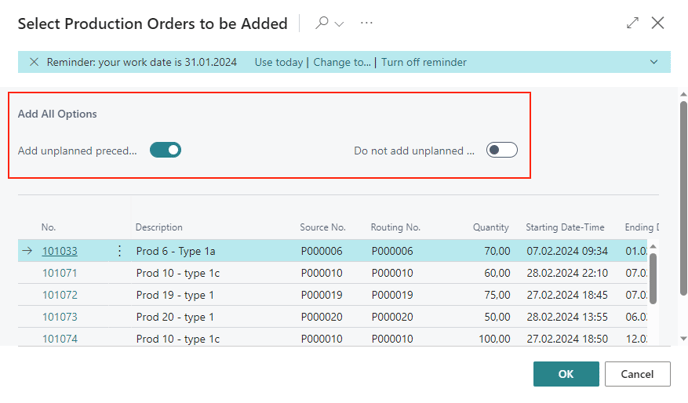

Two options allow for regulating how preceding and/or succeeding linked production orders are treated:

-

add unplanned preceding production orders first

-

do not add unplanned succeeding production orders

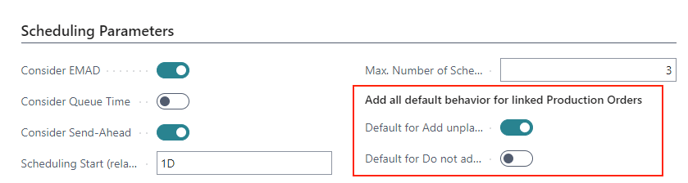

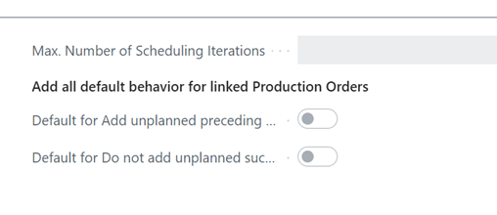

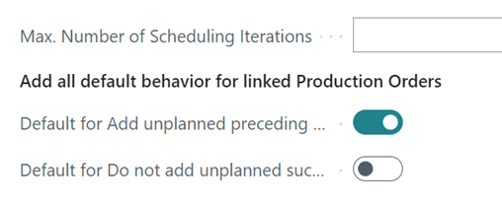

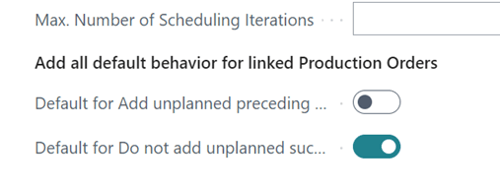

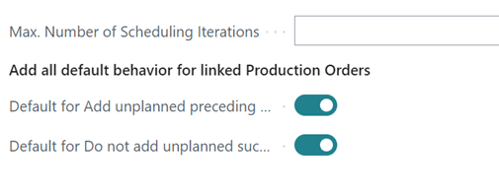

These options can be defined as default settings via the VAPS setup:

The overview below lists all possible combinations and their respective effects.

|

NEVER schedule predecessors/

|

|

Always schedule ALL predecessors

|

|

NEVER schedule successors or predecessors

|

|

NEVER schedule successors

|

However, in the "Add all" dialog, you can also spontaneously determine a deviation from the standard specifications every time you schedule new production orders via the "add all" function.

All procedures described above, also apply when you want to take into account alternate machine centers: